ID Solutions – Barcode & RFID

ID Solutions – Barcode & RFID

An effective asset management solution begins with tagging your assets and equipment with a label or unique identifier. This facilitates the asset’s visibility to end users in the field, during audit and verification tasks and through all stages of the asset lifecycle.

ID Solutions – Barcode & RFID

The ideal tagging and scanning technology choice, barcode or RFID, depends on;

- Frequency of scanning in the assets lifecycle

- Environment the tag will endure; indoor/outdoor, heat, weather exposure, chemical exposure, UV stability

- Surface materials and wear & tear during the assets operation

- Size & proximity of tags to readers for efficient scanning

- Visibility and anti-theft properties

Getting the technology mix right will deliver significant cost saving and productivity gains to the organisation’s asset management performance.

Considerations

While barcodes may lack many of the more industrious and attractive qualities of RFID, their tried-and-true nature continues to have benefits for many applications, sometimes even in place of RFID.

- Surface composition isn’t an issue with barcodes. They can be designed for curved surfaces, whereas these surfaces can affect an RFID tag’s read range capability.

- Metal surfaces and liquid-filled containers can also present challenges for RFID tags as they disrupt RF waves, but they have no impact on barcode functionality.

- RFID solutions require significant testing to verify that the solution at the desktop or workshop, translates with the same effectiveness in the field.

- Barcodes take less time & cost to implement than RFID. You can start improving your asset management much faster with quicker ROI.

You may want to start your tagging solution with barcodes, and then stagger your RFID implementation when you have fully-integrated asset management systems and procedures in place that cater for redundancy of the legacy barcode system.

The best asset management solution is not simply the most complex one available, but rather one that meets your specific identification needs.

Barcode Labels

The barcode label was developed in 1948 and despite the emergence of the new auto-ID technology’s like RFID & Bluetooth, barcodes continue to be the primary ID and data collection method in industry. With the introduction of the QR code and other 2D barcode formats, the humble barcode’s capacity has been supercharged due to their size, data storage attributes, on screen scanning and smart device interoperability capabilities.

We supply barcode labels in 1D (Linear) & 2D (QR code) formats in all types of materials from plastic to aluminium, security & tamper evident, with a range of laminate, colour & adhesive options.

Customised Label Text, Logos & Sizes

All labels can be customised with your choice of label headers, logos, text, data and number sequences. A complete range of label sizes from 13mm circle to 140mm length are available to suit any asset and equipment size or tracking application.

Please call or submit an enquiry form so we can discuss and quote your barcode label needs.

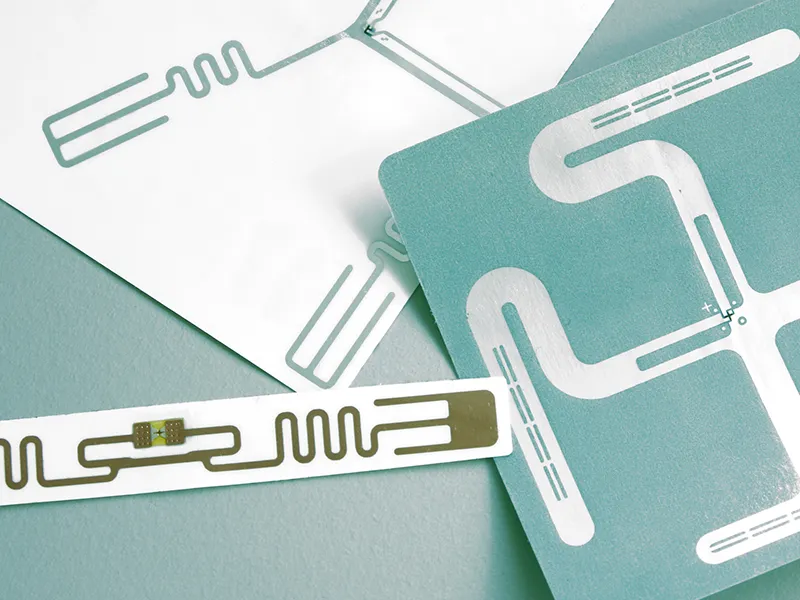

RFID Tags

Radio Frequency Identification (RFID) refers to a technology where information is transmitted wirelessly over radio waves. RFID technology allows users to automatically track and identify assets and inventory via contactless scanning that does not require line of sight to the assets tag.

RFID: What is It and How Does It Work?

RFID systems are made up of three main components: tags, readers and middleware.

Tags; have a small memory chip & antenna, storing bits of valuable data for asset management or other applications. They use radio waves to communicate with nearby readers, transmitting portions of identifying data. The information stored in RFID tags can range anywhere from a single serial number to multiple pages of data.

Readers; are devices with one or more antennas that emit their own radio waves and scan the signals of any RFID tags within range. They receive those radio waves from the tags and then translate that signal back into useful data to facilitate the information exchange. Readers can be mobile or fixed and built into existing infrastructure eg. cabinets or doorways.

Middleware; serves as the essential interface between the reader and your asset database. It handles communication between the reader and your asset systems and helps filter, aggregate and interpret all of the data coming from the RFID tags.

RFID systems can vary in performance based on their frequency. There are three main frequency ranges for standard RFID systems.

Low Frequency (LF); the simplest and most basic option available. Can range anywhere from 30 to 300 KHz, with very short read ranges eg. centimeters, and have limited data transmission capabilities. Typically used in applications such as livestock tracking and simple access control.

High Frequency (HF); they can range anywhere from 3 to 30 MHz, but 13.56 MHz is the standard frequency due to the near-field communication, or NFC, protocol. Greater read ranges than LF eg.a meter and larger memory options. Popular in marketing and interactive experiences, critical access control and data transfer applications.

Ultra-High Frequency (UHF); frequency range from 300 MHz to 3000 MHz and offer the most complex and high-performing capabilities of the frequency ranges. They have the greatest read ranges, which are largely dependent on the type of tag used.

While RFID offers benefits beyond barcodes, it’s usually not an either or scenario. In fact, using both barcodes and RFID systems in your asset management solution can help with data redundancy. Once you have an RFID system set up, minimal investment is needed to add a barcode to an RFID tag. Having the barcode information programmed into the RFID chip can also add extra redundancy for peace of mind.

When it comes to RFID, there is no such thing as “one size fits all”. To optimise asset management accuracy, RFID solutions should be tailored to meet the unique needs of your application. Tag size, read range, frequency and ability to work on specific asset surfaces must all be taken into account when specifying an RFID tag.

Please call or submit an enquiry form so we can discuss and quote your RFID label needs.

Let Asset Track Australia’s experienced team assist you in determining the best tagging option to suit your environment and asset tracking objectives. We have a huge range of label & tag options to suit all environments. With our technology partners, we’ll deliver the right solution that works.

Let’s Talk

Need a better way to track and manage your assets?

Book a Free Consultation and get the right asset management solution for your business.